Four Properties of a Coated Abrasive

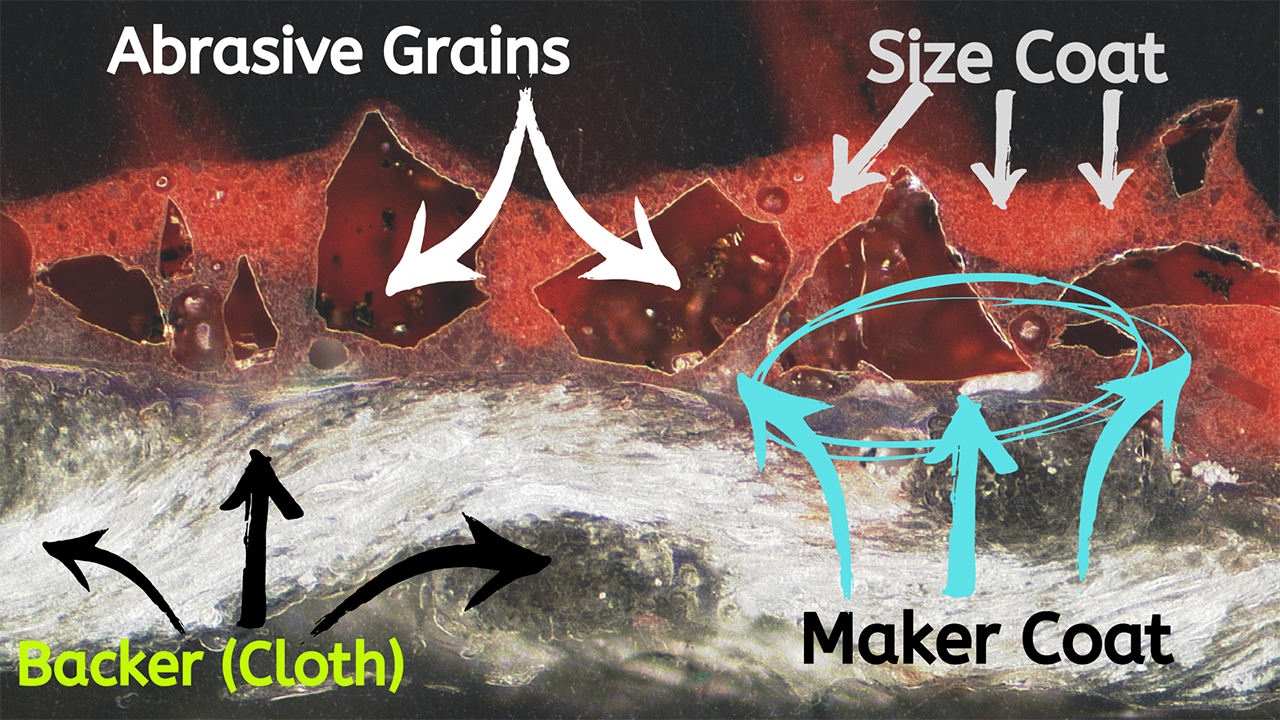

Size Coat

The second layer of adhesive bonding, referred to as the size coat has two main purposes. The first is to tie the individual grains on the abrasive face together, so that they act as a unit instead of as individual grains. The other function of the size coat is to act as a heat shield for the grain. As previously discussed, most of the bonding agents in coated abrasives are phenolic resins, which after curing, are heat resistant.

Too much size coat or too little size coat can cause performance and finishing issues. Too much size coat and the grain won't be able to cut, instead creating a shiny effect on the abrasive's surface often resulting in burning of both the abrasive and the workpiece. This is called glazing. Too little and the grains won't act as a unit and will shed individually under pressure. Glazing and shedding are primary indicators that something may have gone wrong during the application of the size coat.

Size coat is also where several optional steps may occur. These would include but not be limited to the addition of dyes, stearates and lubricants. Size coat is a critical part of the making process that can have far reaching affects on both the life and finishing properties of coated abrasives.

Abrasive Grain

A substance used for abrading, grinding, polishing, lapping, such as the natural materials Emery, Garnet, Flint, and Crocus, and the manufactured or electric furnace materials: Aluminum Oxide, Silicon Carbide, and Alumina Zirconia.

Maker Coat

The maker coat is the first layer of adhesive bonding in the maker process. The purpose of the maker coat is to provide a seat for the grain that will be applied in the electrostatic coating process. In other words, it is what adheres the grain to the backing. Most of the bonding agents today are synthetic resins and are phenolic which ensures a sturdy, heat resistant point of connection between the grain and the backing.

Backer Cloth

A flexible or semi-rigid material to which abrasive grain is bonded.

Recent Posts

-

The Burning Post

Hello Pyrographers! It’s been a while since I sent out a Burning Post News …May 28th 2024 -

Turning Point: How Woodturning Empowers Veterans

In the aftermath of military service, many veterans struggle to find their footing in civilian life. …Nov 8th 2023 -

Getting Started with Power Carving

Power carving is a type of wood carving that uses power tools to remove wood more quickly and ef …Sep 20th 2023