Abrasives 101 | AZ-Plus Alumina Zirconia | Klingspor's Woodworkingshop

Klingspor Abrasives PS36 ( AZ-Plus ) is a stearate coated, semi-open coat Alumina Zirconia on a paper backer. Alumina Zirconia is a tough grain like Aluminum Oxide, but has a property of being hard and brittle like Silicon Carbide called "Friable." This means that when you start with 60 grit, the grain gets under pressure it breaks like an icicle, revealing a fresh new part of the grain that is still 60 grit. From here it slowly wears down like AO making it longer lasting than other abrasives. Being a Semi-Open coat allows for loading to occur and having a stearate coating (Blue in this case) allows for that loading not to stick and glaze the abrasive.

If this abrasive is better than most why not just sell it and nothing else?

AZ-Plus being aggressive causes issues with bare wood, especially if finishing with stains or dyes. It's the sharp grain that breaks causes deeper scratches than AO in the same grit range. Now, this doesn't mean you can use it on bare wood, you can but you would have to follow up after with AO to smooth out the scratches. When we make AZ in belts we call them Planer Belts which refers to the heavy stock removal of wood. From 24 to 60 grit these belts will dimension surface grain quickly. 80-120 will smooth out those scratches. You can ever get this aggressive abrasive for Drum Sanders. For bare wood applications, it's best to stop at 120 with AZ-plus and continue with our Stearated Aluminum Oxide Discs.

| Shop Planer Belts | Shop Abrasives Drum Sanders | Shop Stearated Aluminum Oxide Discs |

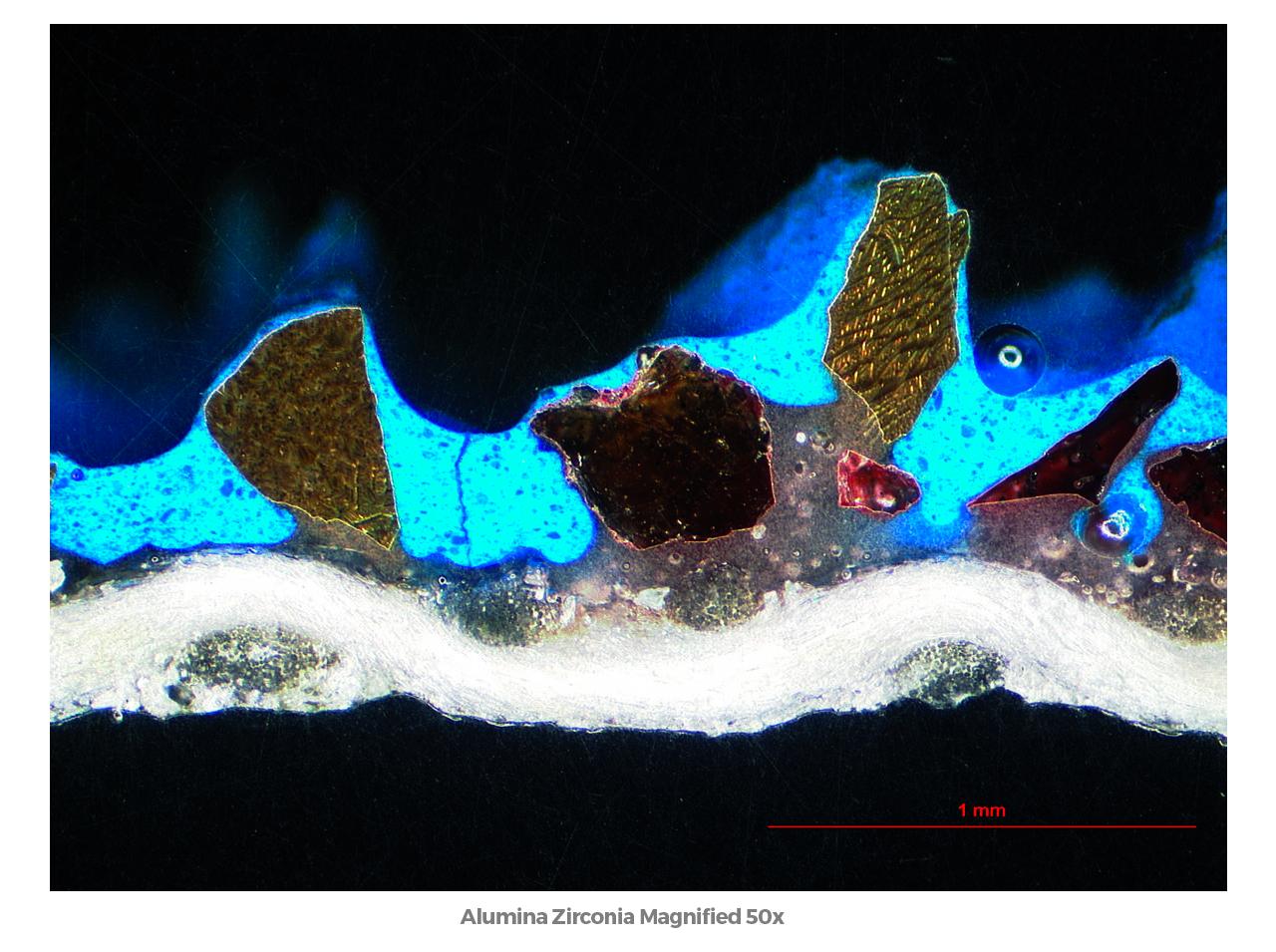

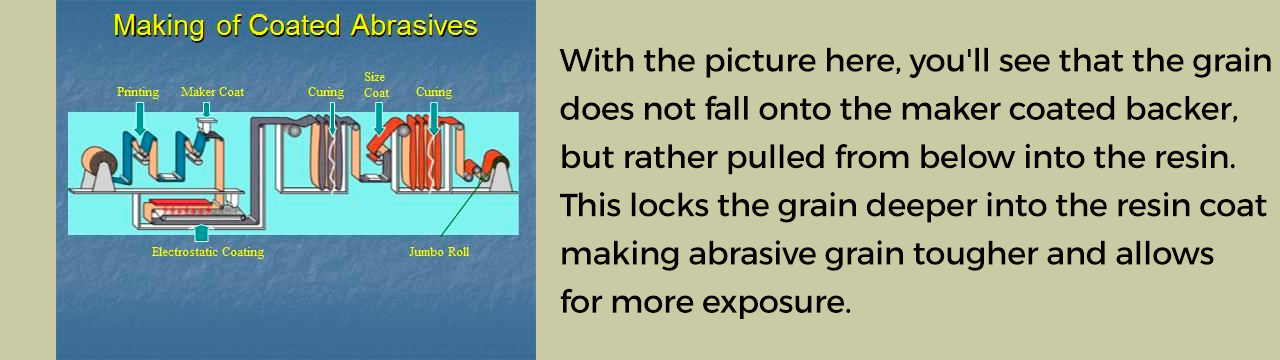

Resin Over Resin (ROR) coating is how the abrasive grain is applied and locked onto the backer substrate. With the AZ-Plus Stearated abrasives, you have a phenolic resin maker coat applied to the paper backer, which then the AZ is electrostatically aligned perpendicularly, for maximum grain exposure and a size coat of phenolic resin is applied over top to lock in the AZ grain.

Sanding bare-wood, you should always use an open (50%) to Semi-Open Coat (75%) abrasive. The disc on the left is a Semi-Open Coat AZ-Plus while the disc on the right is a closed coat (100%) You'll notice that these discs, used for the same amount of time on the same wood (American Black Walnut) have different loadings across the disc.

Do you carry AZ-Plus for my disc sander?

We manufacture our own abrasives which both saves you money and gives you options other manufacturers may not. We stock 5"x8 Hole, 5"x5 Hole, 6"x6 Hole, 5" No Hole, 6" No Hole and for Festool we have 5"x9 hole, 6"x 9 Hole, 6"x 17 Hole & 6"x 48 Hole patterns.

If you don't find what you're looking in AZ-Plus please contact us.

Recent Posts

-

The Burning Post

Hello Pyrographers! It’s been a while since I sent out a Burning Post News …May 28th 2024 -

Turning Point: How Woodturning Empowers Veterans

In the aftermath of military service, many veterans struggle to find their footing in civilian life. …Nov 8th 2023 -

Getting Started with Power Carving

Power carving is a type of wood carving that uses power tools to remove wood more quickly and ef …Sep 20th 2023