Abrasives 101 | Silicon Carbide | Klingspor's Woodworking Shop

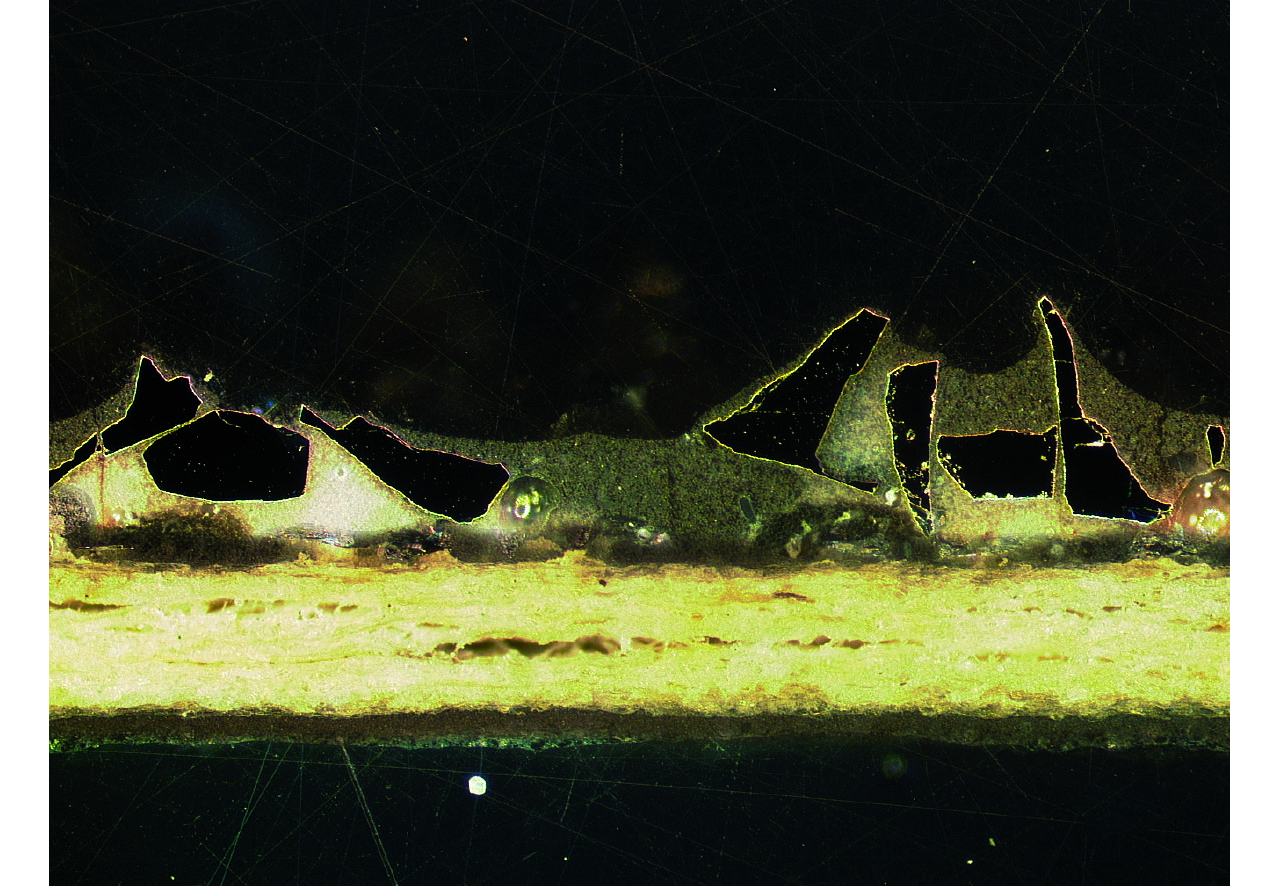

Silicon Carbide Magnified 50x

Klingspor Abrasives Silicon Carbide is a sharp, very hard, brittle and closed coat abrasive. Best suited for sanding glass, plastics, rubber, ceramics, solid surface and between coats of finish. Also used with some non-ferrous metals, sharpening of alloys, stainless steel and tooling steel.

Silicon Carbide is also sometimes referred to as Wet/Dry sandpaper. First made popular in the automobile industry in the early 20th century, SC has been widely used across many industries. Due to its very hard properties (Almost as hard as diamond) it can cut rather than plow through many materials like glass and plastic. However because it's so hard, it's also very brittle. This brittleness allows for a property called "Friable" which means when it breaks or fractures, it exposes a new part of the grain. What this means is a consistent scratch, when you start sanding with 120 grit, it remains 120 grit for the duration of the service life of the abrasive.

Due to the brittle nature of SC, it can break under light pressure. Make sure to not force workpieces into the abrasive or press down too hard when using a hand applicator like a rubber block. Light pressure will allow the abrasive to do the work and last longer. This is also the reason it's not recommended for bare wood applications. SC will break off in wood grain and the scratch is deep. It will show up especially when you stain.

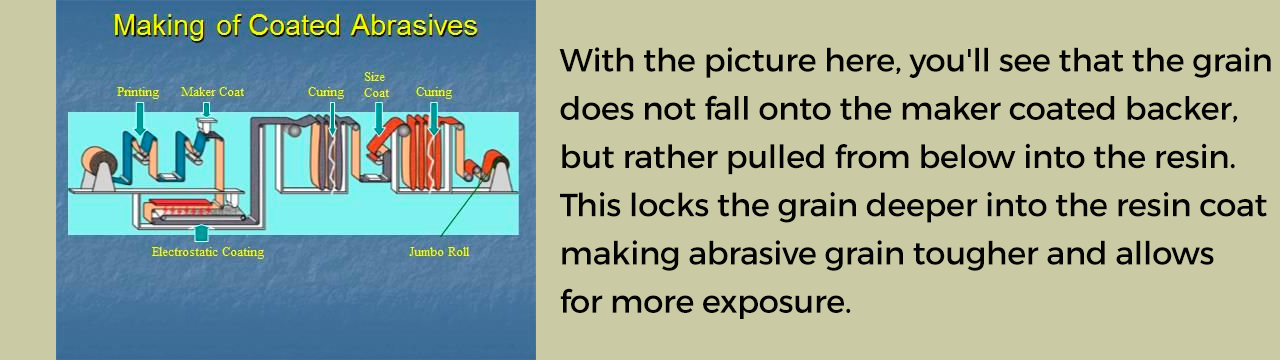

Resin Over Resin (ROR) coating is how the abrasive grain is applied and locked onto the backer substrate.

With our abrasives, you have a phenolic resin maker coat applied to the backer, which then the SC is electrostatically aligned perpendicularly, for maximum grain exposure and a size coat of phenolic resin is applied over top to lock in the SC grain.

Sanding bare-wood, you should always use an open (50%) to Semi-Open Coat (75%) abrasive. The disc on the left is a Semi-Open Coat while the disc on the right is a closed coat (100%) You'll notice that these discs, used for the same amount of time on the same wood (American Black Walnut) have different loadings across the disc.

Wet/Dry Silicon Carbide can be found in Sheets, Discs, Foam Pads, Fusion Foam and Belts.

Stearate Coating

Dry application Silicon Carbide with Stearate Coating can be found in Sheets and Discs.

Recent Posts

-

The Burning Post

Hello Pyrographers! It’s been a while since I sent out a Burning Post News …May 28th 2024 -

Turning Point: How Woodturning Empowers Veterans

In the aftermath of military service, many veterans struggle to find their footing in civilian life. …Nov 8th 2023 -

Getting Started with Power Carving

Power carving is a type of wood carving that uses power tools to remove wood more quickly and ef …Sep 20th 2023